Rubber mould manufacturing company located in India. We manufacture Rubber moulds for precast boundary

walls and Multipurpose applications and provide machines, chemicals, training, and complete technical

assistance to set up precast plants worldwide.

Our other products are rubber moulds for pavers, floor tiles, wall tiles, Curb stones, Manholes, Drain

slab, Plastic mould, pvc moulds, and other moulds for concrete products.

Easy-to-cast compound walls, seamless demolding, and hassle-free installation with our high-strength rubber moulds.

Rubber mould solutions for Industrial boundary walls, residential designer boundary walls, Graden fences

We don't just supply Rubber moulds — We provide complete precast unit setup, including:

Our Rubber moulds are designed using precision-engineered CAD/CAM models, ensuring every panel or column you cast maintains uniform thickness, clean edges, and smooth finishes — no chipping, no warping, no rework.

Whether yo're casting one wall or one thousand, the quality stays consistent.

We use a proprietary rubber blend that's tough yet flexible. It resists wear, cracking, and deformation — even after hundreds of casting cycles.

No hammering, no breakage. Our Rubber moulds offer effortless demoulding that

speeds up your production line.

Less downtime = More output = Better profits.

Time is money in precast — and we help you save both.

Whether you need plain, brick-style, woodgrain, cobblestone, or even your logo embedded, we can deliver. Our in-house R&D team works with you to create moulds that match your design and project requirements.

Forget high-maintenance rubber moulds. Our non-stick rubber surfaces make cleaning simple — with just water or light detergent. That means less labour and no expensive release agents.

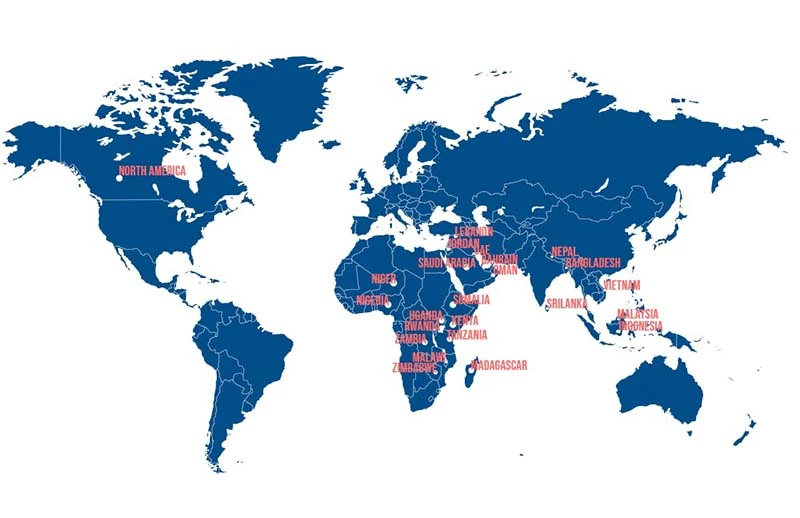

From India to Africa,Asia and the Middle East, our boundary wall rubber moulds are helping developers, contractors, and infrastructure agencies deliver faster, stronger, and more aesthetic wall systems.

Trusted in over 30+ countries

We have precast unit for training of end to end production and installation of machines in various locations. Other than these locations ,we have trained technicians to help you setup prodicto anywhere in the world.

Thrissur city, Kerala State, India Nairobi, Kenya Goma- DRC Niamey - Niger Danang - Vietnam

Our client base extends to all states of India, and 34 countries worldwide.