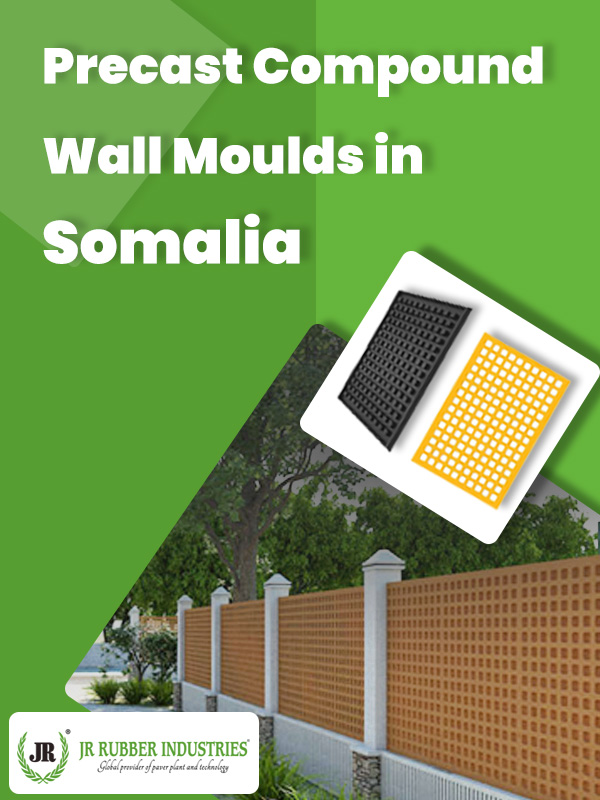

In Somalia, the construction industry is evolving rapidly, and with it comes the need for innovative solutions like Precast Compound Wall Moulds from Jr Industries. These moulds offer exceptional efficiency, durability, and design flexibility, addressing the growing demand for robust and aesthetically pleasing boundary walls in the region.

The demand for durable, visually appealing, and quick-to-install compound walls is rising in Somalia. By choosing Jr Industries, you can take advantage of this opportunity to establish a strong presence in this emerging market and achieve significant success. Our expertise encompasses more than just mould making—we provide machinery, chemicals, training, and comprehensive technical support to help you set up and operate a successful precast manufacturing unit in Somalia.

Innovation in the Construction Field by Jr Industries

Somalia's construction sector is witnessing remarkable growth, driven by urbanization and infrastructure development. In this context, the adoption of Precast Boundary Walls presents numerous opportunities. These walls, produced off-site using specialized rubber moulds, offer significant advantages over traditional construction methods. Here's why prefab boundary walls are becoming increasingly popular and what possibilities they bring to Somalia.

The construction boom in Somalia, fueled by urban growth and infrastructure projects, creates a promising environment for the production of prefabricated boundary walls. As an entrepreneur or business owner, investing in this area not only meets the rising demand but also offers a profitable business venture.

Precast Compound Walls offer several benefits:

Precast compound walls are versatile and used in various applications:

Since 1994, Jr Industries has been a leading manufacturer of rubber moulds for precast boundary walls. Based in India, we offer not only moulds but also machinery, chemicals, training, and full technical support to help set up precast manufacturing units globally, including in Somalia.

Proven Track Record: With years of experience in the industry, we have honed our expertise in producing durable and high-performance rubber moulds.

Technical Proficiency: Our team of experts ensures that every mould meets the highest standards of quality and precision.

Durable and Strong: Our rubber moulds are built to last, ensuring long-term use and consistent performance.

Flexible: Designed for ease of casting and demoulding, making the production process smoother.

High Finished Products: Achieve zero-damage, high-strength panels due to the unique vibration transfer properties of our rubber moulds.

Amazing Design Options: We offer a variety of design combinations to suit different aesthetic and structural needs.

Inbuilt Colored Panels: Easily cast colored panels at the factory for a polished look.

Industry Leader: Recognized as one of the world's largest rubber mould manufacturers, our reputation for quality and reliability speaks for itself.

Customer Testimonials: Hear from satisfied customers who have successfully used our products and services to enhance their businesses.

Certifications: Our moulds and manufacturing processes meet international standards, ensuring you receive only the best products.

Training and Installation: We provide complete training and installation support to ensure your success.

Technical Assistance: Continuous technical support to address any challenges and optimize your operations

Easy-to-cast compound walls, seamless demolding, and hassle-free installation with our high-strength rubber moulds

Durable Rubber Moulds

Industry-Grade Chemicals

Advanced Machineries

Essential Accessories

Expert Installation Support

Hands-On Training

Continuous Future Support

Are you considering entering the precast mould manufacturing business in Somalia? Jr Industries provides the ideal solution to start your journey with confidence. While starting a new venture can be challenging, our advanced rubber moulds and comprehensive support can help you navigate these challenges and seize the opportunities in this sector. Our moulds are designed for efficiency, durability, and ease of use, ensuring high-quality production that meets market demands.

By partnering with Jr Industries, you gain access to cutting-edge technology, training, installation support, and ongoing technical assistance. We empower you to establish a successful precast mould manufacturing business in Somalia, addressing market needs and setting new standards in construction efficiency and quality.

Looking to optimize your existing construction operations? Jr Industries offers tailored solutions to enhance your efficiency and expand your capabilities. By incorporating our advanced rubber moulds into your operations, you can streamline production, reduce costs, and improve project timelines. Our moulds are known for their precision, durability, and versatility, helping you meet diverse project requirements with ease. Whether your projects are residential, commercial, or infrastructure-focused, our moulds enhance quality while minimizing environmental impact. With Jr Industries as your partner, you can elevate your construction operations in Somalia, ensuring sustainable growth and maintaining a competitive edge.

As urbanization accelerates in Somalia, there is an increasing need for efficient and durable boundary solutions. Precast boundary walls meet this demand by offering quick installation, reducing construction timelines, and improving site safety.

Precast boundary walls are cost-effective due to reduced labor costs, minimized material wastage, and efficient construction processes. This translates to faster project completion, allowing developers and contractors to meet deadlines and cut overhead costs.

Precast boundary walls offer significant flexibility in design and customization. Developers and homeowners can choose from various designs, textures, and finishes to complement architectural styles and enhance property aesthetics.

For entrepreneurs and investors, entering the precast boundary wall manufacturing sector in Somalia presents exciting business opportunities. By partnering with Jr Industries, you can access advanced mould technology, comprehensive support services, and training to establish a successful manufacturing venture.